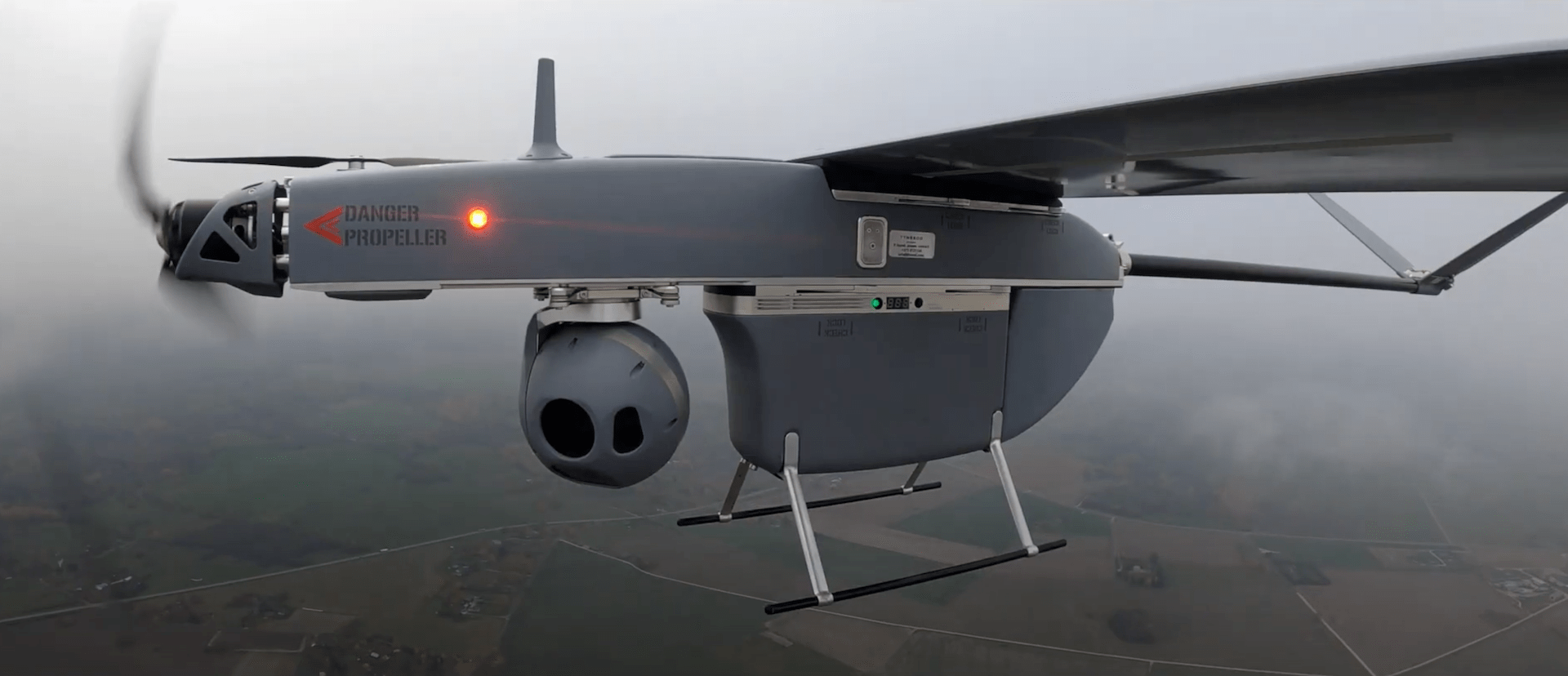

Threod Systems is a developer and manufacturer of Unmanned Aircraft Systems (UAS), covering both fixed and VTOL Unmanned Aerial Vehicles (UAVs), electro-optical payloads for reconnaissance and surveillance applications, as well as a range of other critical subsystems required for the successful operation of UAVs.

Ensure efficient dust removal when processing fibre-reinforced plastic parts, both manually and with CNC machine tools. Optimise the automatic operation of the filtration system based on machine signals, improving process efficiency and reducing energy consumption.

Challenges of the project:

The following factors had to be taken into account in the design and calculations:

- The materials are processed in two adjacent rooms, where the work is carried out at different times and for different cycle lengths.

- The limited space available made it necessary to develop a compact and space-saving filtration solution that would not compromise productivity and performance.

As a solution, a system was introduced where air exchange takes place according to a set constant pressure. Based on signals from the CNC benches, the appropriate valves in the piping are opened automatically, ensuring the stability of the negative pressure regardless of the number of machines in operation. As a result, dust extraction is always at maximum efficiency and energy efficiency is always achieved.

For the project, we used a GramCleanAir filter from the Danish manufacturer GramCleanAir's FL series, which was chosen as the ideal solution due to its wide range of applications and reliability.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia