The inevitability of manual sizing is uneven lubrication cycle!

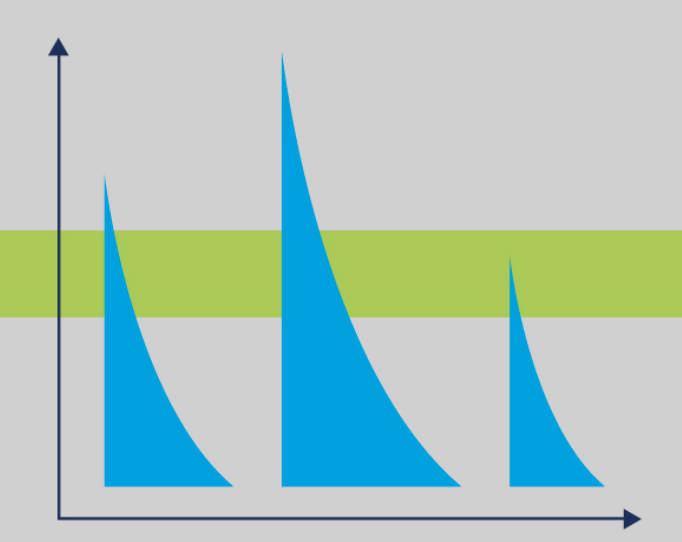

An uneven lubrication cycle causes waste of lubricant, allows pollutants to enter the camp, causing premature wear and significantly affecting bearing life.

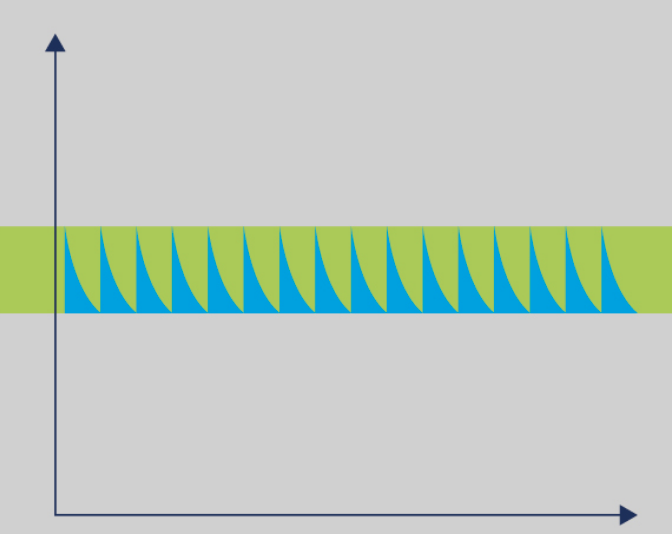

This is where automatic lubrication comes into play, ensuring that. optimum lubricant quantity, thus avoiding over- and under-estimation.

Automatic continuous lubrication extends the life of bearings and prevents unplanned downtime. Small, frequent amounts of lubricant during bearing movement. prolong bearing life.

Choosing a manual lubrication system for your industrial applications can. esmapilgul seem like a cheap solution. However, when all the problems involved are taken into account and compared with the advantages of an automatic sizing system, the latter ultimately proves to be the most profitable solution.

Averaging systems are widely used in a variety of sectors, including. industry, in transport and in energy production. They help to ensure longer machine life, reduce maintenance costs and improve productivity.

Contact us to discuss the specifics of your machinery and equipment and your expectations for mid-range systems. Our experts can provide detailed information on systems Costs and benefits and help you understand how these systems can help your business. We can also discuss project payback times and how mid-range systems can help. reduce maintenance costs.

We represent a US manufacturer GRACO lubrication technologies in Estonia. GRACO has been involved in the development of this field since 1926, and the company's beginnings date back to the invention by one of its founders of the pneumatic lubrication gun, which today is a common tool in every machine maintenance workshop.

We're ready to help you make the right decision and find the best solutions for you. Specifically on needs.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia