The client needed a solution for metalworking benches to remove the fouling and emulsion generated during the process. In total, there were 8 pinki, which produced both chemical and mechanical particles in the air. This created the need for a safe and efficient extraction system to improve working conditions and keep the production environment clean.

Result: The installed solution ensures that all the contaminants generated by the 8 machine tools during the work process are effectively removed. The air in the room is cleaner, working conditions are healthier and the production process is more environmentally friendly.

Our team designed and installed a system that ensures the removal of the pollution generated during the process:

GRAM CLEAN AIR filter FL 104 - a solution that filters air of pollution and returns it to the production process as clean air. This helps reduce harmful emissions and creates a healthier working environment for workers.

Oil shales OUF - devices installed on each relevant machine tool to trap emulsion and other wet mechanical particles by centrifugal force, preventing their release into the air.

Automated management - the system is equipped with pressure sensing and signal-based start and stop of the machine tools, making the solution energy efficient and user-friendly.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

The client wanted to build effective and working welding ventilation "corner of the fire". The previous solution of two separate fan coils offered only a limited radius of operation and did not cover the entire area. A comprehensive solution was needed that would provide a safe working environment, ensure adequate ventilation and take into account lighting and containment needs.

We designed and installed a complete solution to ensure the desired result.

The open area was enclosed by a specially designed structure to which curtains suitable for welding were attached. In addition, both the ventilation pipework and the light fittings were fixed to the structure. For the ventilation, we combined a welded cage solution and a ventilation system. Push-Pull a system that prevents welding gases from spreading to the rest of the building, even without the use of a handle. The core of the ventilation system was GRAM FL 104 filter tower with manual control, to which we added a automatically managed by Welding head type RFF. As a lighting solution, we installed high quality VYRTYCH luminaires, the quantity of which was determined on the basis of light calculations. The result is an efficient and complete welding angle solution.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

We carried out a major upgrade of a ventilation and heating solution for a client in the metal industry. As part of the project, we designed and built a completely new paint room and improved the performance and energy efficiency of the existing drying room.

The client's previous solution was technically and energy inefficient: there was no heat exchanger, the ventilation equipment did not meet the requirements of the working processes and the drying room did not reach the desired temperature.

In addition, the logic of air movement in the drying room was incorrect and the colour room partitions and the air exchange rate were inconsistent with each other, which was not in line with current standards.

The end result was a reliable, modern and energy-efficient system that complies with all applicable safety and working conditions. Both the painting and the drying process now work reliably and cost-effectively. We thank the customer for their trust and look forward to the next challenges!

We built a new ventilation solution for the colour room, using Czech producer CIC Ex-marked equipment suitable for use in potentially explosive atmospheres.

We installed Polish producer Konwektor fans to ensure reliable airflow even under intensive working conditions.

The drying room equipment was rebuilt: we corrected the air circulation logic, upgraded the plumbing and replaced the water node so that the room quickly reaches a uniform operating temperature.

The ventilation unit was replaced with a new one, with plate heat exchanger a solution that will enable us to significantly improve heat recovery and reduce energy consumption.

In both rooms we installed solvent detectors and compressed air meters, which enable control based on air pollution levels and compressed air consumption information, thereby increasing safety.

We installed heat meters for both electricity and heating systems to allow accurate monitoring and logging of consumption.

We applied to the system a completely new automation solution, which also has remote accessso that we can offer our customers real-time support and monitoring remotely.

Filter solution to ensure reliability and equipment preservation:

At the wake-up call we applied double filtering principle, using cardboard filters With W250 with filter matwhich ensure efficient separation of paint and dust particles before they reach the machine.

The ventilation unit itself uses Ex-marked bag filters, which are suitable for explosive atmospheres and ensure high filtration efficiency.

Intake air is used W300 class filter, which keeps the air clean and protects equipment from dirt and dust.

This multi-layered filtration helps to ensure the reliability of the entire system and prolongs the lifetime of the equipment, while reducing the need for maintenance and ensuring a stable workflow under load.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Sami Production is an Estonian mechanical engineering company with over 30 years of experience in manufacturing road maintenance equipment such as snow ploughs, sanders and brushes. The company's products are mainly targeted at the Nordic and European markets.

In the past, we have created ventilation solutions for both manual and robotic welding workstations in Sami Manufacturing's Sauga factory. Positive cooperation experience and the reliability of the solutions provided the basis for the next step - the Valga plant upgrade.

At the Valga plant, the ventilation of the manual welding workplaces had to be solved in two areas, each with 10 workplaces. We installed a Gram Clean Air equipment - cyclone filters with fans - and we designed the push-pull ventilation system. We also made the corresponding air calculationsto ensure that the system operates correctly and efficiently.

In addition, we integrated automation solution, which analyses the activity of welders and triggers the filter system only when welding is actually taking place. This ensures energy savings and a clean working environment.

As a result, the client received a modern, compliant and reliable ventilation solution that helps to keep the working environment clean and the working conditions for welders safe and comfortable.

In addition to manual welding, we also helped the new robotic welding solution by finding the right welding filter, which also ensures a clean environment in the robotic welding area.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

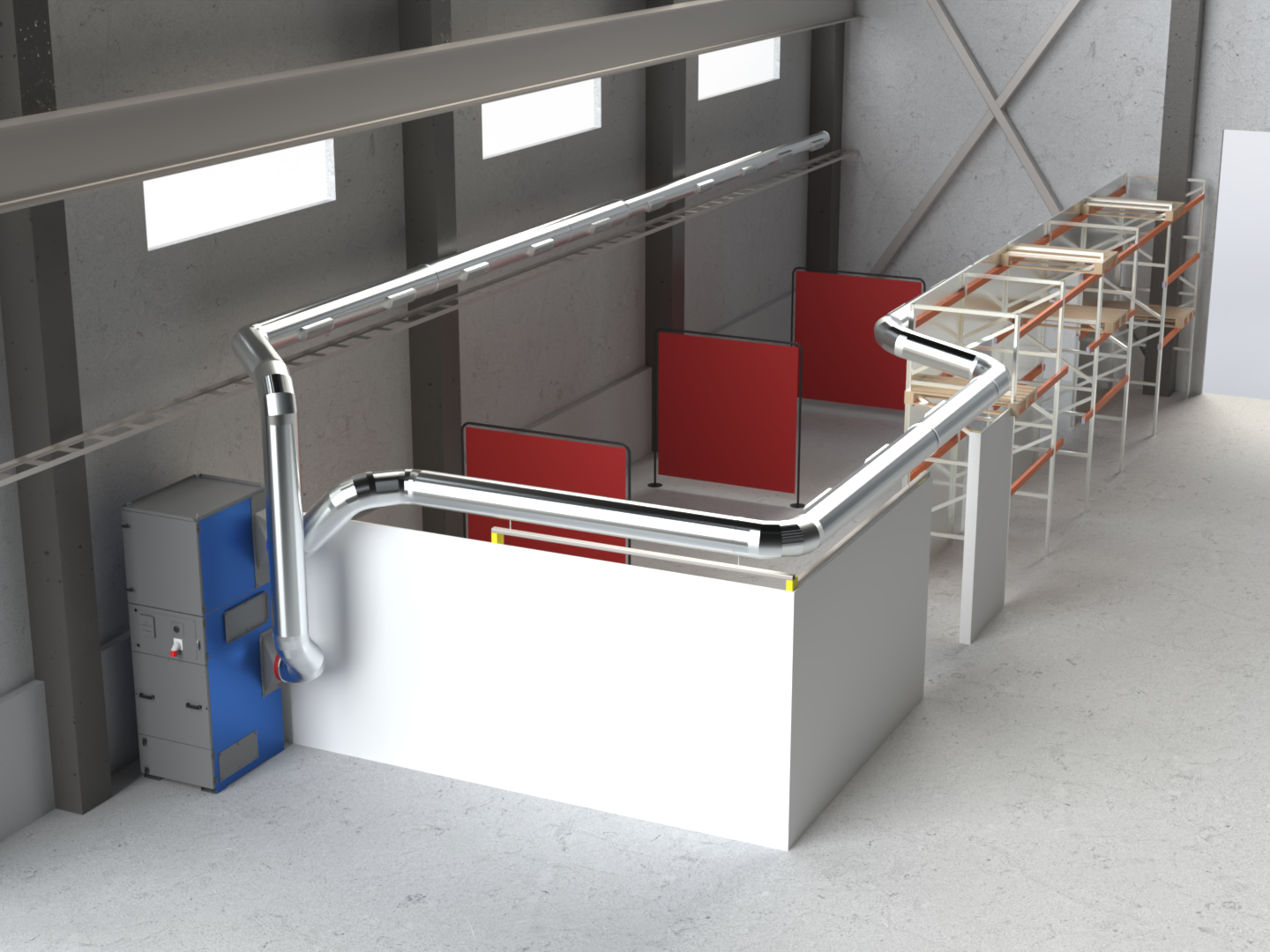

The customer has four welding stations in its production facility where welding fumes are generated during the welding process. All the welding locations are usually working simultaneously and at the same time it was important to maintain the accessibility of the torch throughout the welding area.

We have planned a single PUSH/PULL a ventilation system that allows the removal of fumes and gases without disturbing the production process.

To filter the air, we installed a reliable Danish manufacturer GRAM FL filter unit, which is Plug & Play solution - quick to install and ready to use.

The solution ensures controlled air movement and effective cleaning of welding fumes throughout the working area.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

AQ Lasertool OÜ is a company belonging to the Swedish AQ Group, which has 5 factories in Estonia, two of which are located in Pärnu, two in Jüri and one in Viimsi.

There was a constant demand for heating in production and the compressor was running daily - the residual heat from the 55 kW unit was previously unused. Cost-benefit calculations showed that the heat transfer to the heating system of the building would provide a very fast return on investment, so it was decided to implement the solution.

We channel heat energy into both domestic hot water and heating water. All parameters are adjustable.

We installed an automatic heat control system in the oil cooling circuit of the compressor, which regulates the temperature of the oil and the domestic hot water by means of four sensors. The system optimises the heat exchange and prevents the compressor from overheating. A built-in heat meter accurately measures the energy returned. The system can be routed to both the domestic hot water and the building heating system.

The amount of energy recovered amounts to 10 MWh per month on average. Expect an even bigger result in the winter months, as the higher temperatures in the heating system allow more efficient heat transfer due to the small temperature difference. The projected annual residual heat input is more than 120 MWh, which means significant savings in heating costs and CO₂ reductions.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Sami Production carried out a major modernisation project, investing nearly EUR 9 million Upgrading and expansion of the Valga plant. One of the key elements of this investment was New automatic powder coating line designed and installed by Elister, which played a key role in optimising the plant's production processes and increasing productivity.

The company's production facilities were previously located in both Saue, Otepää and Valga, but in order to improve production efficiency it was decided to Otepää factory to be closed and production to be concentrated in the town of Valga. This enabled investment in the expansion of the Valga plant and the introduction of modern technological solutions, including a new paint line.

The case was 4000 m² of new construction and a reconstructed area of the same size., which provided the opportunity to integrate state-of-the-art production solutions.

The previous dye line was the "bottleneck" of production, as it did not allow for the dyeing of large products, which limited production capacity and efficiency.

New automatic powder coating line installed removed this obstacle by allowing:

The choice of colour scheme was an important part of the project. Compared to traditional wet painting, powder painting offers several advantages:

The choice was also customer demand, as many customers, especially in Finland, prefer powder-coated products.

Our system not only improves production efficiency, but also reduces environmental impact.. An important part of the system is heat recovery, where the residual heat from the paint line furnace is not wasted, but is used to. for the heating of production halls and welding halls.

Advantages of the system:

Our contribution was not limited to the installation of the paint line. We have previously also helped Sami Produce the development of welding ventilation, robotic welding and manual welding workstations in both Valga and Saue..

Some of the key projects:

💡 Elister - innovative industrial solutions to improve production efficiency and sustainability!

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

When an unexpected fire hit the paint rooms at Konesko's Koeru factory, a major challenge was faced. The production process was severely disrupted and the situation required a quick and efficient solution. Our task was to help the customer to overcome the crisis and to create completely new painting and drying rooms that meet today's requirements and ensure safe and efficient production.

The main objective of the project was to create two functional colour spaces - one for large and heavy products and one for smaller and lighter ones. In addition, the rooms had to be equipped with drying facilities and ensure efficient ventilation, lighting and remote control of equipment. All the equipment had to comply with the requirements for Ex-proofing and the work had to be carried out without interrupting daily production.

How did it all happen?

The work was carried out in two phases. First, we built a painting and drying room for larger products. This room was equipped with a powerful 15,000 m³/h Ex-rated ventilation system, which ensures a constant supply of fresh air and efficient air exchange. For future needs, we also added the possibility to easily integrate a cooling function. The equipment in the room was mounted on a special fire-resistant metal structure, separated from the rest of the production area by fire-resistant walls. All the solutions complied with the requirements for Ex-proofing.

For the processing of larger products, Konesko has added an Ex-ready shelf to the colour room, making it easy and convenient to lift and move products. The drying room has been equipped with an Ex-equipped drying solution, which automatically regulates the fresh air flow by means of solvent sensors, ensuring both operational safety and optimal energy efficiency. Proper Ex-lighting was installed in all rooms to ensure optimum working conditions and to allow for high quality production.

In the second phase, we focused on the creation of a colour room for smaller products with an effective air exchange rate of 10000 m³/h and a drying tunnel. In the smaller colour room, we used modern energy-saving solutions, complying with all possible standards and safety requirements that colour rooms need to meet. In addition, the "Power&Free" conveyor system allowed for a fast movement of the products, while ensuring sufficient drying time, as the products in the drying tunnel are not in continuous movement.

The result: innovation and efficiency!

The resulting solution is not just a solution to a problem - it is an example of how a crisis can be an opportunity for innovation. Modern Ex-proof ventilation, lighting and automation solutions ensure energy efficiency, safety and ease of use. Thanks to solvent sensors and compressed air readers, the system optimises ventilation as needed, saving resources when no active painting is taking place.

This project is proof of how, with smart and thoughtful action, it is possible not only to rebuild but also to improve in difficult circumstances. We are proud to have been able to help Konesko at their critical moment and to create a solution that will support their production for a long time to come.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Markland has provided full services for ships, from the construction of spaces to the installation of piping systems.

The production process produces pipe assemblies and modules suitable for installation in ships, boiler houses, power plants, offshore processing of oil products, etc.

The quality system is constantly being developed in line with requirements.

The task was to equip four adjacent welding booths with an individually controlled ventilation solution, while maintaining postcrane serviceability in each booth. In addition, it was important to reduce energy costs and optimise system operation.

For this project, we used the Danish manufacturer Gram Clean Air's FL series welding filter, which is now one of the most common filters for various solutions and was ideally suited for this project.

Each welding booth was equipped with a stand-alone "push-pull" with a solution. We designed the system based on the following principles:

Individual control - when the welding process is started, the valves of the corresponding welding box are opened. At the end of the welding operation, the operation of the corresponding zone is shut down after the post-weld time has elapsed.

Air exchange control - depending on the number of active workstations, the automation controls the fan speed.

Calculations of airflow rates, velocities and head direction to ensure the most efficient exhaust and correct equipment selection.

By optimising consumption, we ensure reduced maintenance costs and energy efficiency.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia