One of Estonia's leading manufacturers of wall systems and door panels, which had previously outsourced the production and finishing of its timber products, wanted to bring the entire production cycle - from milling to finishing - in-house to ensure greater flexibility, quality control and efficiency.

To do this, the client needed full production facilities, which would combine aspiration, finishing and ventilation systems into a single integrated solution.

So the following nodes had to be designed and built:

At first we were only offering aspiration piping, but as we communicated it became clear that Elister is capable and has the competence to offer much more!

The solution allows a company to bring several stages of production in-house, better controlling quality, reducing costs and increasing independence of production.

Elister OÜ supplied and installed a complete system in the new factory, including finishing equipment, dust removal, heat recovery ventilation and drying solutions. All systems were designed and set up to operate in the most automated workflow possible.

The main parts of the system installed:

Aspiration system - NAWARA Ruby low pressure filter device and Formula Air aspiration piping

Low-pressure dust removal system with filter unit and aspiration ducts

Energy-efficient, compact solution with automatic sifter and fan control for clean and safe working air in both hand pumps and automatic lines.

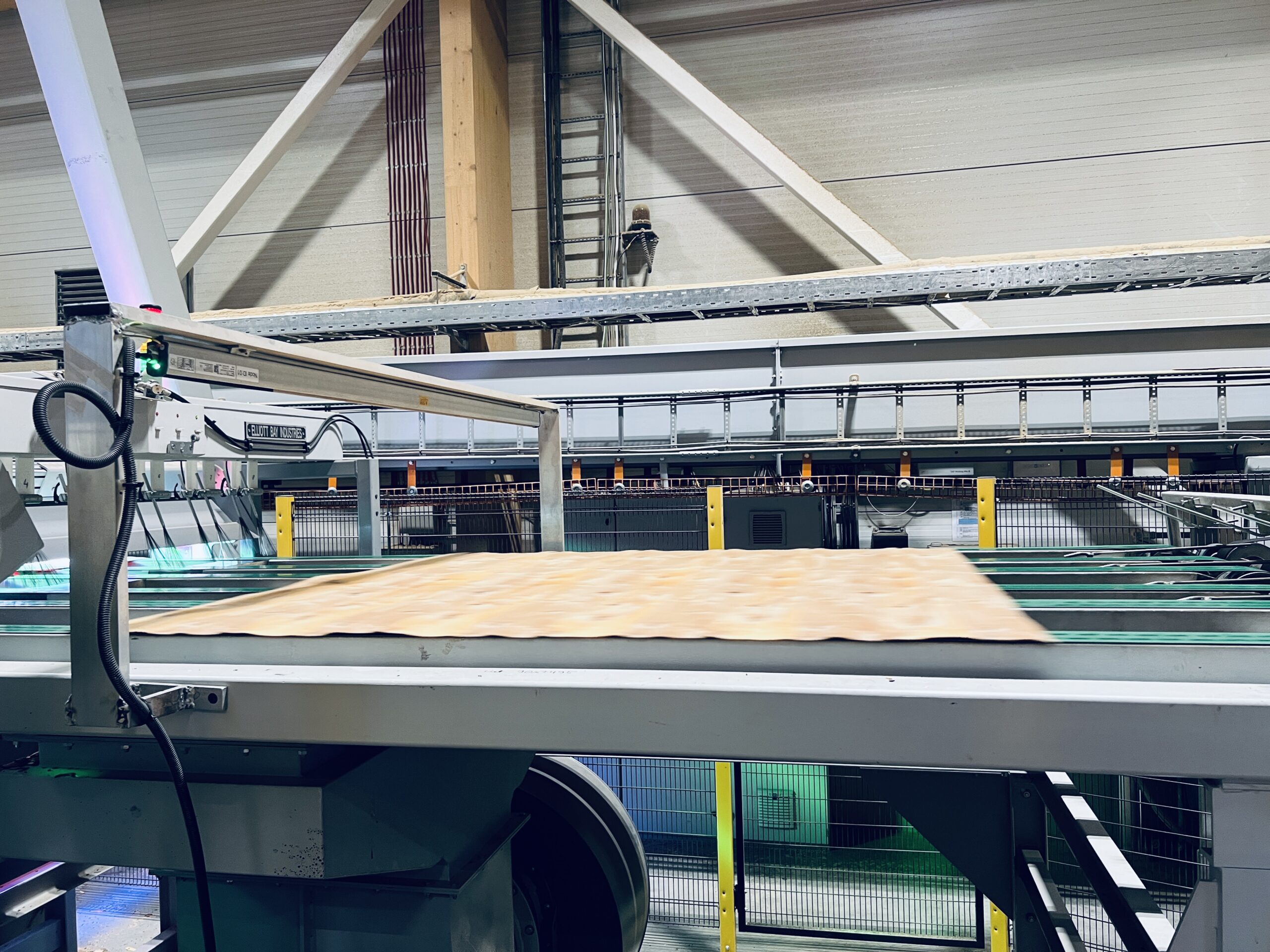

Automatic spray line - Makor Robostart P with LIFT 2P loading/unloading unit

Finish ventilation and drying rooms with thermal adjustment

Drying trolleys and accessories

All the systems were designed according to the specific features of the production building and the layout of the equipment. We created the corresponding 3D models to make it as clear as possible how everything would be completed.

Installation and commissioning was carried out by Elister's experienced technical team.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Static electricity can be a real headache when working with wood surfaces. This project required a solution to a situation where, at work, range of charge up to an impressive 12.3 kV in places, making the process uncomfortable for employees – every touch acted as a small „grounding“ device. This situation was neither safe nor effective.

To solve the problem, we installed two iONstream 4.0 neutralization device – for one lower surface and another upper surface. The result after the equipment was put into use was 400-750V between.

iONstream 4.0 is a unique device equipped with a microprocessor that automatically detects the polarity of the charge and adjusts its operation accordingly.

This solution ensures that excess charge is removed from products as efficiently as possible and that employees are provided with safe and stable working environment.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

A client renovated their production facilities in the veneering workshop, wanting to equip them with modern and reliable technological solutions.

The aim was to create an efficient, safe and modern working environment, which supports production quality and efficiency.

The main needs that we were competent to address:

woodworking machinery dust and chip removal or aspiration system,

gluing ventilation and spraying technology,

production premises irrigation systemto ensure the correct moisture level in the veneering and bonding processes.

The client wanted solutions that would energy efficient, safe for working in Ex zones and easy to maintainwhile ensuring stable working air quality and better working conditions.

The client's veneering shop received an efficient, modern and reliable system that supports both the quality of production and the comfort of the employees. All the systems - aspiration, ventilation, spraying and humidification - work in coordination with each other, ensuring a stable production environment. Customer feedback has been very positive, particularly in terms of system reliability and ease of use.

For the extraction and dust removal from the wooden benches we used Formula Air aspiration piping and fibres.

For dust filtration and extraction we installed Nawara VACOMAX S1000 a filtering device that ensures efficient dust removal and clean working air throughout the production area.

For the bonding area we designed and installed Ex-zone compliant water-heated tile ventilation system with heat exchanger in the finish, where the work takes place in a 3 metre wide cabin.

Controls air exchange and ventilation specially designed finishing automation, which monitors solvent and compressed airparameters, ensuring operational safety and optimal air exchange.

To ensure lighting in the workplace, we installed Ex-tsoon 2 meet the requirements luminaires, which ensure 1000 lux luminous intensity. Luminaires have glass covers, which are easy to clean and resistant to industrial environments.

For glue spraying we supplied GRACO Mercury 30:1 Finishing pump, equipped with PerformAA with finishing gun - this ensures a uniform spray and a high quality finish.

To ensure the right humidity in the production rooms of the veneering workshop, we supplied and installed. UNIFOG with two zones irrigation system.

The system uses 2,2 l/h spray nozzles, which are installed stainless steel piping ensuring a durable, hygienic and precise irrigation solution.

Such a system helps to maintain the required moisture level in the veneering process, which directly affects the quality and reliability of the material.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

The client wanted a comprehensive overview of their production aspiration solution. All the equipment was connected behind a single filter, which was causing low air velocity in several workstations and consequent problems in the production process. The piping was being built out gradually as new equipment was added and there was no project documentation reflecting the actual situation. The aim was to map the whole system, check the air velocities, calculate the air requirements and distribute the equipment between the two filters to ensure a reliable and efficient aspiration solution.

A comprehensive set of documents is handed over to the client, including a detailed piping diagram, measured air velocities and any other data required for future use.

In the course of the project, we drew the entire aspiration piping with the necessary calculations. A large number of old lines were removed and replaced with new piping that was in line with the design. Unnecessary penetrations were closed and the equipment was distributed between the two filters according to their importance. Following the installation work, measurements were carried out to check that the system was in accordance with the design.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Our goal was to design and implement a solution that would remove the fine dust generated by the chipper directly from the place where it is generated. The need was to reduce cleaning/maintenance requirements and keep the room dust-free.

We took advantage of the customer's existing aspiration filter, and designed a new aspiration pipework and a hood above the machine. On the cube we used removable fins.

In order to ensure that the machine is also accessible for maintenance work, the cube was placed on a rack, which allows it to be moved and ensures easy access.

In addition, we installed an extraction nozzle in the room, which allows the fine dust to be directed directly into the existing filter during cleaning.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Nordwood is a common trademark of three sawmills - AS Viiratsi Saeveski, AS Viru-Nigula Saeveski and AS Aegviidu Puit - combining high quality sawn timber produced from Nordic pine and spruce logs. Nordwood's products are used both in Estonia and in export markets in the construction industry and as raw materials in the furniture, packaging and timber industries.

Cool production space and permanently open doors

Elister received a request from Nordwood in autumn 2024, when there was a problem with cool working conditions in one of its production units. The specific nature of the production building - constantly open doors - made finding an effective heating solution a challenge. The wind tunnel created by the open doors resulted in a high heat loss and maintaining the working temperature proved difficult.

To solve the problem, we installed three industrial water-heated air curtains from Metmann in Nordwood's production building. These units are capable of circulating up to 25 000 m³/h of air in the room, providing uniform heat and reducing the inflow of cold air through open doors. The solution not only improved working conditions but also reduced energy consumption while keeping the room at a comfortable temperature.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Customer satisfaction is our top priority and it is a great pleasure to work on projects that are similar to previous ones - it shows we have done something right. We were recently approached by a customer for whom we had previously supplied two booths of hand-finishing booths with a drying tunnel. The customer now wanted a similar solution, but with some adjustments.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Elister OÜ is a leading player in the Estonian market in the field of equipment and systems sales, design, testing and relocation. Our company specializes in creating high quality solutions that meet the highest industry standards. The weight of the equipment handled by Elister's experts can exceed 50 tons, which demonstrates our ability to manage large projects.

With a wide range of services, we would particularly highlight our care team. Maintest skills that ensure the long-term performance and efficiency of equipment. Our services are not limited to the projects we are directly involved in selling. With our technical expertise and extensive experience, we are also a sought-after partner for equipment from other national manufacturers.

Internationally, we have provided support to producers in Switzerland, Denmark and Italy.

A recent notable project was the construction of a CNC line at the Essepig plant in Italy. After successful testing in Italy, we installed the same line in Viljandi Akna ja Ukse production plant in Estonia. We got the system up and running before the factory representatives arrived to complete the fine tuning. We made a video report on the success of the project.

Elister OÜ is not just a service provider, but your trusted partner for equipment and systems.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia

Founded in 1997, Puidukoda is a French-capital based planing industry based in South Estonia, specialising in the production of high value-added softwood timber. production and marketing of planed wood (spruce, pine and larch).

In 2023, we started working with representatives from the Woodshop to discuss the design of a new production building ventilation system that would include heat recovery.

In the building, which contained one of their paint lines, the aim was to use the heat energy generated by the painting process, to compensate for the vacuum created and to remove the high humidity associated with the use of autoclave.

We installed an efficient plate heat exchanger ventilation system with automatic pressure control and regulation.

The system is programmed to support the operation of the paint line or control the humidity in the room as required, operating fully automatically without additional operator intervention.

Thanks to this innovation, the company can continue to use its existing heat source, the boiler, without the heat load exceeding the boiler's capacity.

This is a big step forward for both productivity and sustainability.

Any ideas that could be reviewed together? Contact us

Come and visit us at our Jüri office at Kesk tee 10, Jüri, Rae vald, Estonia